| |

Get Back to Work Safely with These

COVID-19 Safety Essentials from Saf-T-Gard

|

| |

|

| |

The first "P" in "PPE" stands for

"Personal", and never before has safety been more personal than it is

now with the outbreak of COVID-19 affecting the lives and livelihoods of

everyone.

No one understands this better than Saf-T-Gard International, Inc. After

all, safety is rooted in our name. So when it comes to your workers' safety, you can trust that

Saf-T-Gard has everything you need to get back to work worry free, including the following:

|

| |

|

We've been bringing workers home safely for more than 80 years, and we can do the same for you!

Click here to shop our selection of COVID-19 Safety Essentials to Keep Your Business Running online, or call customer service at 1-800-548-GARD (4273) today for more information or to place an order or with any additional questions on how we can assist you in your worker safety program.

|

| |

|

| |

Did You Know 80% of Electrically-Related Accidents Involving Qualified Workers Are Caused by Arc Flash Hazards? |

| |

|

| |

Don’t test your luck when exposed to arc flash and electrical

safety hazards. Test your rubber gloves for continued safety, compliance and savings

with the Voltgard® Test Lab!

Rubber gloves must be tested every six (6) months according to

ASTM-F496 and to protect against loss time, costly damage, legal liability,

increased insurance premiums and hefty regulatory fines.

Saf-T-Gard is uniquely qualified to service all of your arc

flash, electrical safety and dielectric testing needs with its Voltgard® Test Lab – The

largest, independent, NAIL4PET-accredited test lab in the United States for the

complete testing and recertification of rubber insulating gloves for continued

use – all to applicable ASTM standards, including:

In addition to stocking the largest inventory of new rubber

goods, Saf-T-Gard also offers a comprehensive selection of head-to-toe Personal

Protective Equipment, Facility Safety, First Aid and Arc Flash and Electrical

Safety to accommodate all of your safety needs for whatever the job requires!

Visit www.saftgard.com today to learn more!

|

| |

|

| |

|

How to Prevent Cross Contamination |

| |

|

| |

Cross-contamination risk is a major concern in the food supply

chain. The transfer of potentially deadly bacteria, viruses or other toxic

substances can have catastrophic outcomes, so minimizing the likelihood through

adherence to solid food safety practices is essential.

These risks are especially prevalent in processing environments

including meat production, wherein the base product is a common carrier of

bacteria, and therefore demands that adequate preventative measures be in

place.

Despite the prevalence of potential hazards at every step in the

chain, most instances of cross contamination are entirely preventable provided

a thorough quality system that incorporates good manufacturing practices is in

place. That system should incorporate provision of personal protective

equipment (PPE) including suitable hand protection. Click here to watch the video and learn more on

how to prevent cross contamination.

|

| |

|

| |

|

What Type of Face Covering Should I Use?

|

| |

|

| |

Remember the stone ages when we all just went around spitting in

each other’s faces like a bunch of angry alpacas? That’s so 2019 BC (Before

COVID).

Most of us understand by now that covering your mug is the way

to go, but it can be tough to decipher between all of the options available. At

the end of the day, not everyone needs a N95 – but everybody needs something.

So how do you choose which face mask is best for you? Click here

to read a recent blog post on face coverings by Ergodyne to learn more.

Saf-T-Gard supplies a comprehensive selection of Ergodyne seasonal

protection. Click here to shop them online, or

call customer service at 1-800-548-GARD

(4273) today for more information or to place an order.

|

| |

|

| |

|

How to Select A Safety Harness |

| |

|

| |

The safety harness is the main component of a personal fall

arrest system. Before purchasing a harness, you should be aware that

everything, from harness construction to webbing type and position, varies

between harnesses and their manufacturers. Purchasing a harness that is

complicated to put on or uncomfortable will reduce the likelihood that your

workers will wear it.

Click here to read the Honeywell Miller white paper

to make the right choice for the harness your workers will be willing to

use.

Saf-T-Gard carries a wide range of Honeywell Miller fall protection

products, including harnesses, lanyards, self-retracting lifelines, anchorage

points and fall protection accessories. Click here

to shop them online, or call customer service at 1-800-548-GARD (4273) today for more information or to place an

order.

|

| |

|

| |

|

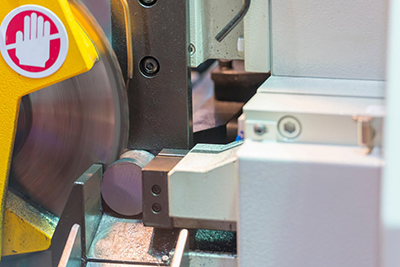

Five (5) Expenses You'll Avoid by Investing in Machine Safety |

| |

|

| |

Cost avoidance is defined by any action taken in the present

that prevents incurring greater costs in the future. For example, routinely

investing in machine safety to remain in compliance with safety regulations is

a form of cost avoidance.

Unlike immediate cost savings, cost avoidance

measures are not reflected in financial statements or annual budgets. They are

nevertheless important to a company's profitability. When cost avoidance is not

exercised, companies can face several potentially catastrophic expenses.

These include:

- Lost time wages and lost customers due to production constraints

- Increased worker's compensation rates

- Medical bills

- OSHA fines

- Litigation and settlements

These costs can be unrecoverable and cannot be forecast due to

the large number of unknown and unpredictable factors that can contribute to an incident. Despite

this, machine safety is often seen as an expense rather than an investment. It

is not a product or solution a factory can use to generate sales, so it does

not positively impact the bottom line. It is, instead, a way to protect your

assets (including your employees) from future adverse consequences. This article will break down each of these five (5) expenses

that can be incurred when cost avoidance is not executed for machine safety.

Lost Time Wages and Lost

Customers

Lost time wages and lost customers go hand in hand. When an

accident occurs, the company is responsible for maintaining the employee’s

wages in order to minimize the impact of the incident on their life. This means

the company will maintain payroll without the positive result of meeting the

customer's need.

To avoid losing a customer, then, other trained workers need

to do overtime to compensate for the decline in production rates. This also

requires additional administrative time to manage shifting responsibilities,

priorities and training.

Worker's Compensation Rates

Worker's compensation is a type of business insurance that

provides coverage for medical expenses, lost wages, and rehabilitation costs

for employees who have suffered from a work-related injury or illness. This

type of insurance is compliance-driven, but also protects employers from

lawsuits.

Some insurance companies encourage machine safety by offering lower

rates to companies that implement it. Be sure to research this option to help

reduce this recurring expense, as well as avoiding increased premiums due to

filed claims.

Medical Bills

Medical bills are a variable that is not always fully considered

by the insurance companies. There is potential for post-accident in-network versus

out-of-network costs, increased deductibles, emergency transport, and service

fees – all depending on where the accident took place. The company is typically

tasked with the direction of the medical care but challenged with not creating

additional inconvenience and decreased comfort for the affected employee.

OSHA Fines

OSHA reports that machine safety is one of the top 10 most violated

regulations in the industry. OSHA standards are meant to ensure a safe environment for

workers. Too often, however, these rules are ignored until there is a need to

react to a negative event. This is usually met with fines ranging from

thousands to millions of dollars, depending on the severity of the violation.

Litigation and Settlements

Litigation and settlements are the most expensive and the

ugliest portion of the cost avoidance formula. Companies want to take care of their employees, but when an

accident occurs they often shift to a defensive position. This requires support

of an internal legal team or an external law firm focused on job-related

accidents. Consultations, payroll for fact finding, and negotiations are all

time-sensitive costs that add up quickly. Court costs and associated

expenditures may be incurred if negotiations are unsuccessful.

Ultimately a settlement of some sort will be paid out for pain and

suffering for the employee and their family. This is an undesirable outcome

that negatively affects the company's bottom line.

Machine Safety Cost Avoidance

Cost

avoidance is important to secure the profitability of any facility. The

benefits of investing in machine safety more than outweigh the initial costs.

To

ensure the costs are calculated properly for funds appropriation, be sure to

work with a qualified turnkey safety guarding company. These companies can

provide education, recommendations for required safety upgrades, and full

designs and quotes. They can also help you create and implement your machine

safety plan. It is a small cost for a rich future.

|

|

|

|

|

|

|

| Coronavirus Response |

|

|

|

|

A new OSHA video provides five (5) tips to keep workers safe

during the holidays. Click here

to watch it now.

|

|

|

|

Happy Holidays from

Saf-T-Gard

|

|

|

|

|

For this holiday season, we have made significant donations in

the names of Saf-T-Gard employees, customers, suppliers and business associates

to help those in need, benefitting: Habitat for Humanity, Gratitude Generation,

Greater Chicago Food Depository, Northern Illinois Food Bank and The Rotary

Foundation Disaster Relief Fund. Wishing you a safe and happy holiday season

from all of us at Saf-T-Gard!

|

|

| |

|

| Saf-T-Gard Catalog |

|

|

|

|

The time for better safety is now!

Click here to request a FREE copy of our current full-line Saf-T-Gard International, Inc. catalog today, and learn how to better GARD yourself with Saf-T-Gard.

Featuring more than 3,900 different line items from more than 100 different brands and fourteen (14) different product categories, this catalog is an excellent resource and provides a wealth of information to help keep you safe and productive for even the most rigorous applications!

|

|

| |

|

|

|

| Closeout Corner - Don't Miss These Great Deals |

|

|

|

|

Saf-T-Gard is making it easier than ever to save big on your favorite safety items with the "Closeout Corner" featured monthly in the Saf-T-Gardian e-Newsletter.

Click here to view the reduced pricing on all of your must-have items to take advantage of this limited-time pricing and inventory.

Be sure to check back next month for even more products and savings!

|

|

|

|

|

| Safety Tips |

|

|

|

|

COLD IS COMING - And that means hand protection for outdoor workers

should have warm linings

COLD IS COMING - And that means head protection for outdoor workers

must include warm helmet liners

COLD IS COMING - And that means fewer hours of daylight and reduced

visibility - another reason for Hi-Viz reflective clothing

COLD IS COMING - And that often means icy, slippery walkways and

driveways - tungsten-carbide tipped rubber pullovers fit over any shoes or

boots for superb traction

COLD IS COMING - And yes, that means colds are coming, so be sure

you have enough industrial-pack cold remedy medicines on hand

|

|

| |

|

| Q&A |

|

|

|

|

|

Question - "Are switchboard mats recommended or required by OSHA for use in

commercial office building electrical rooms?"

Answer - The OSHA standard makes no reference to commercial office building

electrical rooms. However, OSHA does incorporate specific references to

the ASTM D178 specification for Rubber Insulating Matting in 29 CFR 1910.137

(Electrical Protective Devices) and 29 CFR 1926.951 (Tools and Protective

Equipment). ASTM D178 is the Standard Specification for Rubber Insulating

Matting. Where there is a risk of exposure to energized circuits in a

commercial office building electrical room, appropriate protective equipment is

required under the General Duty Clause and other references. At a minimum,

we recommend switchboard matting, rubber insulating gloves, and NFPA 70E arc

flash clothing and equipment for the appropriate hazard rating.

|

|

| |

|

| Saf-T-Gard Spotlight |

|

|

|

|

Ray Jackson is a Customer Service Representative and has been with

Saf-T-Gard for more than ten years.

What Ray likes about Saf-T-Gard:

"The people I work with. Everybody is friendly and

helpful. It's a good group of people."

What makes Ray's day:

"When I know that I've been able to help a customer, even

if it's something simple."

Ray's outside interests are:

"Golf,

camping, reading and spending time with friends."

|

|

| |

|

Factoid Factoid |

|

|

|

|

What is OSHA's position regarding the required "quiet time"

before audiometric testing is done? Can an employee's audiometric testing

be conducted after the employee has worked a full shift in a noisy environment,

and was wearing hearing protection?

The Occupational Noise standard at 29 CFR 1910.95(g)(5)(iii) states that

testing to establish a baseline must immediately be preceded by fourteen (14)

hours without workplace noise. There is no requirement for fourteen (14) hours

without exposure to workplace noise for annual audiograms as there is for

baseline audiograms.

However, please be aware that a temporary threshold shift (TTS) could

possibly contaminate an annual audiogram if an employee was exposed to noise

prior to taking the audiogram. It is this audiogram which is compared to the

baseline audiogram to determine whether a Standard Threshold Shift (STS) has

occurred. The audiologist, otolaryngologist, or physician cannot override this

STS determination simply because of possible TTS contamination. Only a retest

audiogram, taken within 30 days of the annual audiogram, can be used to replace

the annual audiogram and the STS determination.

An employer may substitute

the use of hearing protection when the fourteen (14) hours of quiet time cannot be

met. If TTS contamination is a problem, the retest audiogram should be preceded

by fourteen (14) hours free from workplace noise, (but this is not required by the

standard). If no retest is done, the annual audiogram and its STS determination

are conclusive, and the follow-up procedures and written notification of the

STS determination to the employee must be done.

|

|

| |

|

| As I See It |

|

|

|

|

It is December 2020, and I am in a reflective mood as 2020 comes

to a close and we prepare for the New Year.

What a year! COVID-19 has certainly changed our lives. A year

ago, I venture to state that the acronym PPE rarely made the front pages of the

daily newspapers or cable news channel. A year ago, there were plenty of

disposable gloves and N95 masks to fill demand (and a year ago who outside of

the safety industry knew what N95 meant?).

But here we are wrapping up 2020, so the first order of business

is to extend heartfelt thanks. To our Saf-T-Gard customers – everything we do, we do for you. We pride ourselves on being a customer-centric organization. We

appreciate your business and strive to constantly exceed your expectations. We

have explored every option to ensure that we could continue to supply you with

the PPE that your workers need in spite of COVID-19-driven product shortages.

To our Saf-T-Gard suppliers – thank you for your continuing

support. We’ve had our challenges – every business does – and when we work

together for the benefit of our mutual customers, there is most likely no

problem that defies resolution. And to the dedicated and talented Saf-T-Gard

team – thank you for your commitment to excellence and for your adaptability

during this unusual year.

This is all another reminder that we never forget that the first

P in PPE stands for PERSONAL, and it is for the personal relationships with our

customers, suppliers, and Saf-T-Gard associates that we are so grateful. We’re

looking forward to the New Year 2021 – our 85th year of pride in the

fact that we are Saf-T-Gard International – Bringing

Workers Home Safely Since 1936.

|

|

|