|

Step up Your Safety with Savings on These COVID-19 Safety Essentials at Saf-T-Gard |

| |

|

The first “P” in “PPE” stands for “Personal”, and never before has safety been more personal with the Omicron variant having reached unprecedented levels.

Hospitalizations soared to a record high in January 2022. While the numbers are starting to decline, we must remain hyper vigilant about safety, as prevention through the use of PPE is one of the best ways to continue to protect you and your workers.

|

| |

Rest assured, Saf-T-Gard International, Inc. has the essential safety supplies on hand (and with added savings) to help prevent the spread and support you and your employees during the Coronavirus outbreak, including the following:

Click here to shop our selection of COVID-19 Safety Essentials, or call customer service at 1-800-548-GARD (4273) today for more information or to place an order or with any additional questions on how we can assist you in your worker safety program.

|

| |

|

|

|

Understanding Testing and Rating of PPE Rubber Insulating Gloves |

| |

|

| |

Tested,

arc-rated, shock protection, class, AC, DC, ASTM, OSHA, and more – what do they

all mean?

Live-line

working at distribution voltages up to 34.5 kV AC requires the finest-quality

protective equipment to keep the line worker safe. In the United States, OSHA

specifically mandates the use of rubber insulating products and related tools

and equipment that has been manufactured and tested to specifications developed

by ASTM International, a consensus standards organization. Many ASTM standards

have also been approved as American National Standards and covered products are

often marked with a dual ANSI/ASTM label.

Users of

rubber insulating gloves, for example, are accustomed to seeing a color-coded

label indicating a voltage class (00 – 4) and a maximum usage voltage when

working on AC equipment. The specifications driving that class and voltage data

provide for a significant margin of safety. For example, gloves rated class 2

for working voltages up to 17,000 volts AC are 100% proof tested at 20,000

volts AC and samples of each production batch are tested to withstand at least 30,000

volts AC.

AC vs. DC

– A deep dive into the ASTM standards shows test voltages and maximum use

voltages for both AC and DC. While there is no fixed formula relating the AC

test and working voltage levels to DC test and working voltage levels, users

can choose either. The reasons for having both AC and DC testing are complex.

AC testing is both an electrical test and a physical test since the current is

passing through the material back-and-forth 60 times per second. This also

creates a corona generating ozone which is harmful to natural rubber. Among the

benefits of AC testing is that manufacturers all test their products using AC

and, most importantly, distribution voltages are AC so “test it as you use it”

makes sense.

Some

engineers postulate that DC testing of rubber insulating products is a purer

test because the DC will find the weakest spot in the rubber exclusive of the

physical effects of AC testing (above). In addition, DC testing does not create

ozone thus eliminating a source of potential damage to natural rubber products.

Of increasing interest is the “test it as you use it” approach to wearing

rubber insulating gloves (and other products) for protection against DC

energized circuits and equipment found in EV (electric vehicles including

hybrid), public transit systems, and renewable power generation.

But what

about those arc-rated gloves? Back in 2013 ASTM approved a test method for

determining arc ratings of gloves used for electrical arc flash protection.

Anywhere from 5 to 10 arc explosions occur every day in the United States, and

as many as 10 workers are killed or injured per day according to some past

research. Arc flash events are a clear and present danger. Exposure to their

intense heat for 1/10 of a second can cause a 2nd-degree burn. Temperatures of

205⁰ F will cause a 3rd-degree burn, leading to complete skin loss in the

exposed areas. A pressure wave blast from a high-amperage arc can travel

several feet with a force of up to 1,000 lbs. That’s enough to toss a victim

backwards, causing injury from falls and impact; it can also cause hearing

loss. Most often, when there is an arc flash hazard there is also a shock

hazard.

About

75% of arc flash incidents occur when a worker is near the equipment. NFPA

reports 2/3 of workers involved in arc flash incidents were injured when

companies failed to conduct an arc flash analysis for selecting PPE. A separate

study found 40% of electrical incidents involved 250 volts or less, so it isn’t

only high voltage that causes injuries. NFPA 70E details areas of protective

clothing sometimes neglected by electrical workers. Jackets and rainwear, worn

over arc-rated clothing should also be arc-rated. Underwear comprised of

meltable fibers such as polyester, nylon and spandex should not be worn.

Sleeves should be fastened at the wrists and shirts tucked into pants. The legs

of pants and sleeves of shirts should come completely down to the ankle and

wrist, forming total coverage when combined with voltage-rated gloves,

protective footwear, safety glasses, hearing protection and hardhats.

OSHA has

required compliance with arc protection standards since 2015. Employers must

calculate the incident heat energy of any potential electrical-arc hazard

exposures to employees and implement programs and systems based on the risk

assessment. NFPA 70E requires specific levels of PPE for various types and

ratings of electrical equipment. OSHA estimates that 80% of

electrically-related accidents and fatalities involving "Qualified

Persons" are caused by arc flash/ arc blast. NFPA 70E is updated every 2

years (2021 is the latest edition).

Click here to read the rest of the article.

|

| |

|

| |

Saf-T-Gard International, Inc. Celebrated 85th Anniversary of Bringing Workers Home Safety

|

| |

|

|

2021

marked the 85th anniversary for Saf-T-Gard

International, Inc., a family owned and operated global

supplier of industrial safety products now in its 4th generation of ownership.

The first "P" in "PPE" stands for "Personal", and

never before has safety been more personal than it is nowadays with the

outbreak of COVID-19 affecting the lives and livelihoods of everyone. No one

understands this better than Saf-T-Gard International, Inc. Since its

establishment in 1936, Saf-T-Gard has enabled on-the-job safety, compliance and

peace of mind for hundreds of thousands of workers and their families by

delivering superior safety products and solutions that protect against

work-related hazards and prevent serious injuries.

Saf-T-Gard has grown significantly since its humble, two-person factory loft

beginnings. Founded as Latex Glove Manufacturing Company by Leo and Lillian

Rivkin, the company began its operations in Chicago when the Rivkins acquired

equipment from a balloon company and used it to produce waterproof,

rubber-coated cotton gloves. They purchased cotton gloves, dipped them in the

latex rubber tanks, let them dry overnight, and sold them the next day. In the

1940s, as Chicago manufacturers geared up to support the American war efforts, Latex

Glove Company expanded its product offering as a full-line industrial glove

distributor.

The focus on occupational safety and health in the 1960s and 1970s lead to an

increased emphasis on providing a full line of personal protective equipment.

As such, Latex Glove Company began supplementing its legacy of hand protection

with industrial safety products from global suppliers, including protective

eyewear, respirators, hard hats, protective clothing and footwear, and first

aid kits and supplies to meet OSHA’s requirements. In 1979, Latex Glove Company

purchased a larger industrial building in Northbrook, Illinois, to position the

company for further growth and better customer service.

In the early 1980s, the Voltgard® project was launched as a small

test lab with the mission to develop the electrical testing and utility

industry business by providing the testing of rubber insulating products to

complement the sales of new products. Saf-T-Gard’s Voltgard®

Test Lab has grown to be the largest, independent,

NAIL4PET accredited test lab for rubber insulating products in the United

States and offers complete retesting and certification of rubber gloves,

sleeves, blankets, line hose, covers, dielectric footwear, jumper cables,

grounding sets, plastic guards, hot sticks, matting, hoods and hand tools – all

to applicable standards. Moreover, the Voltgard® Test Lab developed the Original

Rubber Goods Change-Out Program® – the

industry’s first managed rubber goods change-out program designed to minimize

out-of-service time and save money by offering customers complete solutions

from start to finish. No other test lab offers the Voltgard level of service.

Having experienced significant business growth, Saf-T-Gard moved to its current

location on Huehl Road in 1986. The new building was nearly double in size with

plenty of room for even greater expansion.

By 1989, the company's direction as a full-line, quality-oriented supplier of

safety products was clear, and therefore, Latex Glove Company changed its name

to Saf-T-Gard International, Inc. to reflect its dedication to a complete line

of worker safety products and personal protective equipment. Today, Saf-T-Gard

offers tens of thousands of products spanning the full range of personal

protective equipment and facility safety from the world’s

leading manufacturers in addition to Saf‑T‑Gard’s

exclusive brands. Saf-T-Gard serves customers in all 50 states and in more than

50 countries around the world. The company has received numerous awards,

including Illinois Family Business of the Year, United States Department of

Commerce President’s “E” Award for Export Excellence, AD Safety Network Gold

Star Distributor Award, and AD Safety Network Peak Performance Distributor

Award. Saf-T-Gard is an active member of the National Safety Council (NSC), the

International Safety Equipment Association (ISEA), the North American Meat

Institute (NAMI) Worker Safety Committee, the North American Independent

Laboratories for Protective Equipment Testing (NAIL4PET), the American Society

for Testing and Materials (ASTM), and AD Safety Network.

“Saf-T-Gard is 85 years strong, and our solid history is a testament to our

dedication, commitment and stability as a company,” said Richard Rivkin,

Chairman and CEO, Saf-T-Gard International, Inc. Loren Rivkin, President and

COO continues, “My great-grandparents started our company just after the Great

Depression. World War II ensued and my grandfather went off to war, returning

home with a Purple Heart and Silver Star, and then rejoined his parents’

company. Now we finish our 85th year, hopefully seeing the end of a two-year

global pandemic, and Saf-T-Gard is still here and strong, bringing workers home

safely.”

|

| |

|

| |

Introducing the New Saf-T-Gard® Voltgard® V-APR0 1000 Volt (Class 0) Insulating Apron |

| |

|

| |

Saf-T-Gard

has expanded its Voltgard line of electrical safety products with the arrival

of the Saf-T-Gard®

Voltgard® V-APR0 1000 Volt (Class 0) Insulating Apron.

Designed to provide workers with an additional layer of protection from low

voltage electrical hazards, the Saf-T-Gard®

Voltgard® V-APR0 1000 Volt (Class 0) Insulating Apron is

ideal for use where there is a possibility of accidental contact with energized

equipment or lines.

Additional

features and benefits include the following:

- Made

from a high-strength reinforced Type II rubber material

- Includes

two (2) Kevlar® bib straps and two (2) Kevlar® waist

straps with nonmetallic buckles

- Adjustable

straps can be buckled around the back and around the neck which gives wearers a

comfortable and supportive fit

- All the

straps are attached with reinforced stitching and Kevlar® thread

- Good for

up to 1000 VAC

- Easy to

identify yellow color is highly visible in the work area

- Designed

for situations where there is a possibility of accidental contact with

energized equipment or lines

- Meets

ASTM F2320 standards

- Measures

42” from the top of the bib and has a full width of 30” to wrap around the

front

- One size

fits more wearers

- Sold individually

As a

leading manufacturer and distributor of rubber insulating products, arc flash

safety clothing and kits, grounding equipment and testing services, the Voltgard®

division of Saf-T-Gard International, Inc. is dedicated to serving those where

worker safety and protection from electrical current are critically important.

Click here to shop

the Saf-T-Gard® Voltgard® V-APR0 1000 Volt (Class 0) Insulating Apron online, or

call customer service at 1-800-548-GARD (4273) today for more

information or to place an order.

|

| |

|

| |

February is American Heart Month |

| |

|

| |

Since

1964, Americans have recognized the importance of heart health each February

with American Heart Month.

Every

year, more than 350,000 people suffer out-of-hospital sudden cardiac arrest (OHCA)

in the United States. Of those victims, only about 10% survive according to the

American Heart Association. When a person suffers SCA, they collapse suddenly

and become non-responsive. The heart stops beating regularly, and the brain is

deprived of oxygen. Without intervention, victims of cardiac arrest can die in minutes.

If a person collapses suddenly and is unresponsive, they should be treated with

both high-quality CPR and an AED. Performing high-quality CPR helps to

circulate blood and oxygen to the brain and vital organs.

The

depth and rate of compressions performed during CPR can play a pivotal role in

a victim’s chance of survival. According to the American Heart Association,

compressions should be administered at a rate of 100-120 compressions per

minute and a depth of 2 - 2.4 inches for the average adult. A helpful reminder

is “Push hard and fast!” If you witness someone collapse and become

unresponsive, call 911 immediately and perform CPR until help arrives. If an

AED is available, ask a bystander to bring it, and follow the instructions

included with the device to place it on the victim. The AED will analyze the

victim’s heart rhythm and determine whether a potentially lifesaving shock is

needed. The AHA states that CPR and use of an AED while medical professionals are

en route can directly impact an SCA victim’s chance of survival. For every

minute that passes without CPR, an SCA victim’s chance of survival drops by

7-10%.

Please

help spread CPR and AED awareness during American Heart Month. Every second

counts, and you never know when you might need to help save a life!

When you’re ready to purchase, Saf-T-Gard

offers a wide variety of ZOLL AED Plus® packages including

semi-automatic and fully-automatic options.

Only

ZOLL’s AED Plus® is equipped with Real CPR Help® technology, giving

the rescuer real-time feedback on the depth and rate of chest compressions

during CPR. The sensor in the pads lets the AED see each chest compression and

guides the rescuer, with prompts and a real-time bar gauge, to the recommended

depth and rate of compressions. The ZOLL AED Plus® is available in

semi-automatic and fully-automatic versions, and each package includes a ZOLL

AED Plus® with AED cover, an adult electrode pad (CPR-D-padz®),

(1) sleeve of lithium 123A batteries, a medical prescription and a soft

carrying case.

Additional

features and benefits include the following:

- Novel

electrode design delivers a five-year shelf life and fits 99% of the

population’s chest anatomy

- Pull-tabs

expose the conductive gel on each pad only when it is in direct contact with

the skin, limiting the chance of gel contamination

- CPR-D-padz®

meet applicable ANSI/AAMI/ISO DF-39-1993 requirements and offer clear

anatomical placement illustrations as well as a CPR hand positioning landmark

and comes complete with a rescue accessory package, including a barrier mask,

razor, scissors, disposable gloves and a towelette

- Display

screen presents the elapsed time and number of shocks delivered

- Back-lit

display screen provides simultaneous text with every audio prompt and a circle

of lighted graphical icons that show what to do

A

section of the ZOLL AED Plus® part numbers are as follows:

- 8000-00-4000-01 - AED Plus®

Semi-Automatic Package with Medical Prescription

- 8000-00-4003-01

- AED Plus® Semi-Automatic Package with PlusTrac Professional1

- 8000-00-4004-01

- AED Plus® Semi-Automatic Package with PlusTrac Professional5

- 8000-00-4007-01 - AED Plus®

Fully-Automatic Package with Medical Prescription

- 8000-00-4010-01 - AED Plus®

Fully-Automatic Package with PlusTrac Professional1

- 8000-00-4011-01 - AED Plus®

Fully-Automatic Package with PlusTrac Professional5

Click here to shop

the ZOLL AEDs online, or call customer service at 1-800-548-GARD (4273) today for more information or to place an

order.

|

| |

|

| |

|

Watch the FREE Are Your Gloves up to the Challenge? Assess, Test, Select the Best ON DEMAND Webinar Sponsored by Radians Today |

| |

|

| |

Join

Dave Larimer and Justin Ladd from Radians as they walk you through how to keep

your hands safe in a

variety of different situations. Choosing the right protection for your hands

is usually driven by 5 attributes:

fit and comfort, protection, grip, dexterity, and durability useful life. If

all workers, from medical

to industrial and everything in between, would just wear gloves, then more than

1 million hospital

emergency visits by U.S. workers per year could be avoided.

The key

challenges discussed during this session include:

- Fit /

Comfort – Improper fit causes additional hazards

- Protection

/ Cut Level – Too much? Not enough? Do you know how much you need?

- Grip /

Dexterity – Does the task you’re doing require just a little more?

- Durability

/ Useful Life – Is your team throwing away gloves after every shift? Why?

- Cost –

Total Cost of Ownership – The full picture

Click here to register, and watch

the FREE webinar ON DEMAND today.

|

|

|

|

|

|

|

| Face Coverings 101: Key Differences Between Masks and N95 Respirators |

|

|

|

|

Before

the coronavirus (COVID-19) pandemic, you probably never considered the

differences between a non-medical cloth face covering, a surgical mask and an

N95 respirator. COVID-19 has created a new reality where face coverings

continue to be a part of our daily life.

Click here to

learn more about different types of face coverings, masks, and respirators and

what to consider when deciding how you can help protect yourself and others.

|

|

| |

|

| Shop @ Saftgard.com - The Smart, Simple and Speedy Way to Shop for Safety Online Today! |

|

|

|

|

Saftgard.com makes it easier than ever for visitors to find exactly what they are looking for by utilizing a guided navigation layout with a fully-optimized “smart” search engine. The responsive design enables use and access to more than 6,000 products with enhanced product content and imagery on your PC, smart phone or tablet.

Moreover, existing Saf-T-Gard customers can link their account to a new Saftgard.com web login to review ALL past orders and invoices, create a “wish list” of favorite items, save carts to simplify the ordering/reordering process and so much more! Buyers without an existing Saf-T-Gard account can register for one online, or they can still search, browse and order on Saftgard.com without a Saf-T-Gard account.

We invite you to spend a few minutes at Saftgard.com, and if you haven't already, please register for an account to enable online ordering.

Click here for a shortcut to the registration page, and click here for detailed instructions on how to link your Saf-T-Gard account to a Saftgard.com web login.

|

|

|

|

|

Visit with Saf-T-Gard

|

|

|

|

|

Hazards exist in every workplace. Common examples include slips,

trips, falls, exposure to loud noises, working from heights, vibrations and

unguarded machinery. The best way to protect your employees is to recognize the

hazards that exist on the job, and control them by utilizing the appropriate

personal protective equipment (PPE) for the application.

This is where Saf-T-Gard can

help! We've been bringing workers home safely since 1936 with our finest

industrial safety products and PPE, and we can do the same for you. Stop by our

booth at the any of the following trade shows to check out our comprehensive

selection of safety products and services that directly address every workplace

safety hazard.

Wisconsin Safety Council Annual Conference - Tuesday, April 12, 2022, from 7:30 a.m. to 4:00 p.m. and Wednesday, April 13, 2022,

from 7:30 a.m. to 1:30 p.m., Kalahari Resort, Wisconsin Dells, Wisconsin, Booth

#160

IEEE PES T&D Conference - Tuesday,

April 26, 2022, from 10:00 a.m. to 5:00 p.m., Wednesday, April 27, 2022, from

10:00 a.m. to 6:00 p.m. and Thursday, April 28, 2022, from 10:00 a.m. to 3:00

p.m., Ernest N. Memorial Convention Center, New Orleans, Louisiana, Booth #4511

ASSP Safety - Monday, June 27, 2022, from 9:00 a.m. to 4:00 p.m., Tuesday, June 28, 2022, from 9:00 a.m. to 4:15 p.m. and Wednesday, June 29, 2022, from 8:30 a.m. to 12:30 p.m., McCormick Place, Chicago, Illinois, Booth #1846

International

Lineman’s Rodeo - Wednesday, October 12, 2022, from 8:00 a.m. to 4:00 p.m., Thursday, October 13, 2022, from 12:00 p.m. to 5:00

p.m. and Friday, October 14, 2022, from 9:00 a.m. to 3:00 p.m., Overland Park

Convention Center, Overland Park, Kansas, Booth #217

|

|

| |

|

Five Safety Tips

|

|

|

|

|

1. TAKE A DEEP BREATH - Air-purifying

respirators do not supply oxygen and must not be used in atmospheres with less

than 19.5% oxygen

2. WHAT THE FLOCK? - Chemical-resistant

nitrile, neoprene, and rubber gloves are available with comfortable cotton

flock linings that can absorb perspiration

3. ABSOLUTELY SHOCKING

- If your maintenance staff works on potentially energized circuits,

they need low voltage rubber insulating gloves

4. DON'T FALL FOR THIS - OSHA

requires a personal fall arrest system be used anytime a worker is working 6

feet or more above a lower level

5. CAN IT - Safety cans are

available in a variety of materials and sizes for safe transfer of hazardous

liquids

|

|

| |

|

|

|

|

|

|

Question - Is a "fu-man-chu" acceptable to

have and use a facepiece?

Answer - Tight-fitting facepiece respirators

must not be worn by employees who have facial hair that comes between the

sealing surface of the facepiece and the face or that interferes with valve

function. Respirators that do not rely on a tight face seal, such as hoods or

helmets, may be used by bearded individuals. It does not matter if hair is

allowed to grow on other areas of the face if it does not protrude under the

respirator seal. Accordingly, mustaches, sideburns, and small goatees that are

trimmed so that no hair underlies the seal of the respirator present no hazard

and do not violate [1910.134(g)(1)(i)(A)].

However,

the use of a self-contained breathing apparatus (SCBA) is not acceptable for

bearded employees under emergency conditions. Since the SCBA is used in unknown

concentrations for unspecified lengths of time, maximum protection must be

achieved when the SCBAs are worn. The beard growth can significantly reduce the

service life of the air cylinder on the SCBA which could restrict the

performance in the emergency operation. The SCBA wearer can

"overbreathe" when moderately heavy to heavy workloads are performed.

If there is a leak caused by the beard, the air contaminant could be pulled

inside the facepiece.

Furthermore, the beard can interfere with the sealing of

the exhalation valve and shortening the service life of the air supply. For

emergency use, there is an escape hood with a continuous flow of air and a

fifteen-minute service life which usually can be worn by bearded employees.

Respirators of this type that have been approved by the National Institute for

Occupational Safety and Health are available on the market.

|

|

| |

|

| Saf-T-Gard Spotlight |

|

|

|

|

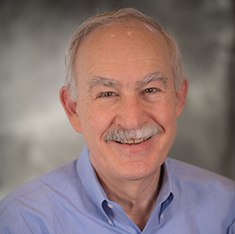

Jack Walker is

Saf-T-Gard’s Key Accounts Safety Specialist, and he joined the company in March

2017.

What Jack likes

about Saf-T-Gard:

“I

really enjoy all of my co-workers. Everyone has a great deal of knowledge and

experience and are experts at their crafts. No matter what needs to get done,

everyone joins together in a team effort to make sure that our customer’s needs

are met well above their expectations. Being new to the company, I was welcomed

with open arms from everyone. There have been many individuals who have gone

above and beyond their duties to make sure that I am comfortable and well taken

care of.”

What makes Jack’s

day:

"The

thing that really makes my day is when we are able to solve a customer’s

problem. Whether that is big or small, helping keep our customers safe and

happy is what we are all about. Most of the times that is working with many

internal business partners to make that happen. Oh, and a good cup of coffee,

or two……"

Jack’s outside

interests:

"There is

nothing better after a long day of work then heading home to see my wife and

three children. Stephanie is my wife, we have been married for more than 6

years and have been together for more than 11 years. Our children are Charlie,

Ben and Molly. We live in Naperville, IL. We spend a lot of time together and

with our family. Outside of family time, I love sports, particularly baseball.

After I was done playing baseball, I began my coaching journey back in 2011.

Currently, I am an assistant baseball coach at Benedictine University in Lisle,

IL. My primary focus is working with infielders and hitters. I am also the

first base coach. As much as I loved to play and compete, there is nothing

better than watching an individual or your team succeed after putting in many

hours of work."

|

|

| |

|

Factoid Factoid |

|

|

|

|

OSHA has previously

maintained the position that hard hats used by employees must be worn with the

bill facing forward unless the hard hat manufacturer certifies that the bill

facing back meets current ANSI Z89.1 standards. Does OSHA still adhere to this

interpretation?

Section 1926.100(a)

provides: Employees working in areas where there is a possible danger of head

injury from impact, or from flying objects, or from electrical shock and

[electrical] burns, shall be protected by protective helmets.

Section

1926.100(b) provides: Helmets for the protection of employees against impact

and penetration of falling and flying objects shall meet the specifications

contained in American National Standards Institute, Z89.1..., Safety

Requirements for Industrial Head Protection.1

In 1992, OSHA stated: ANSI

only tests and certifies hard hats to be worn with the bill forward [;] hard

hats worn with the bill to the rear would not be considered reliable protection

and would not meet the requirements of 29 CFR 1926.100(a) and (b) unless the

hard hat manufacturer certifies that this practice meets the ANSI Z89.1

requirements.

This continues to be OSHA's interpretation of this standard.

Additionally, note that a manufacturer may certify that it would be acceptable

to wear the hard hat with the bill to the rear when the hard hat liner is

turned/reversed.

|

|

| |

|

| As I See It |

|

|

|

|

It is

February 2022, and with apologies to my high school English teachers, we’d like

to explore shoulda and coulda.

If you're reading this, you’re probably involved in some aspect of industrial safety,

either for your employer, your company, or yourself. So unless OSHA is a

foreign language, you know the shoulda (things you should be

doing) and most of them are probably MUSTS, not just shoulda.

It’s when problems like injuries or accidents occur that the shoulda

gains the spotlight. For example, we shoulda had safety mirrors

on the warehouse or we shoulda required better hearing protection

or we shoulda had those rubber insulating gloves tested before

use. Certainly nobody purposely violates a life-threatening rule, but

recognizing the shoulda in hindsight is no excuse.

Besides

the MUSTS, some shouldas are within the supervisor’s discretion

or choice based on experience, training, and analysis and consideration of the

specific situation. So an obvious shoulda is that supervisors and

managers should have regular refresher training that they can impact to their

teams.

And

that’s where some of the couldas come in, often as an explanation

or excuse for why something happened or why a specific choice was made. For

example, I coulda waited until a co-worker was available to

assist, or I coulda performed my gas detector bump test daily

before use.

Maybe

the shoulda and coulda considerations are just

reminders of common sense, but that’s why we train for emergencies – both to

prevent and to respond professionally.

And

here are some easy choices – you coulda called Saf-T-Gard, you shoulda

called Saf-T-Gard, and Saf-T-Gard is ready to help. Call or visit www.saftgard.com today. We are Saf-T-Gard International - Bringing Workers Home Safely

Since 1936.

Sincerely,

Richard A. Rivkin, Saf-T-Gard CEO and Chairman of the Board

|

|

|