| |

Get Back to Work Safely with These

COVID-19 Safety Essentials from Saf-T-Gard

|

| |

|

| |

The first "P" in "PPE" stands for

"Personal", and never before has safety been more personal than it is

now with COVID-19 affecting the lives and livelihoods of

everyone.

No one understands this better than Saf-T-Gard International, Inc. After

all, safety is rooted in our name. So when it comes to your workers' safety, you can trust that

Saf-T-Gard has everything you need to work worry free, including the following:

|

| |

We've been bringing workers home safely for more than 85 years, and we can do the same for you!

Click here to shop our selection of COVID-19 Safety Essentials to Keep Your Business Running online, or call customer service at 1-800-548-GARD (4273) today for more information or to place an order or with any additional questions on how we can assist you in your worker safety program.

|

| |

|

| |

Enter to Win a FREE SureWerx Pioneer® 5408AU Heated Safety Bomber Jacket from Saf-T-Gard |

| |

|

| |

The revolutionary SureWerx Pioneer® 5408AU Heated Safety

Bomber Jacket is made from new 3rd generation Carbon Nanotube

Technology (CNT) heating elements that are extremely thin (5 microns), machine

washable, soft to the touch and flexible with no wires. The heat sensor is

strategically located to accurately measure temperature and prevent over or

under heating.

There are four (4) heat settings (100°F/108°F/118°F/127°F)

indicated by colored LEDs. Simply select your preferred heat setting by

pressing the control button. This jacket is compatible with various power banks

and includes a USB port (power bank not included).

Additional features and benefits include the following:

- Made using 300 Denier Oxford material with polyurethane

coating that is 100% waterproof and 120GSM insulated material with taffeta

lining

- Double-stitched with heat-sealed seams to prevent moisture from

entering the garment

- Exclusive StarTech™ style reflective tape far exceeds ANSI/ISEA

107-15 for high visibility

- Jacket comes in Hi-Viz yellow color with a black bottom to

conceal soiling and offer superior visibility and safety on the job

- Meets ANSI/ISEA Class 3 Type P and R requirements for those

working in dangerous settings where visibility is the highest priority,

including EMS, construction and traffic control

- Heavy-duty coat can be worn as rain or snow work gear and

includes a full-front waterproof zipper, two (2) lower slash pockets with

waterproof zipper, one (1) lower inside zip pocket and lower chest zip pocket,

two (2) radiophone clip straps, three-piece lined detachable hood and elastic

ribbed wrist cuffs and waist

- Available in sizes Small-4XL

Click here to enter to win a FREE SureWerx Pioneer® 5408AU Heated Safety Bomber Jacket, or click here

to shop the SureWerx Pioneer® 5408AU Heated Safety

Bomber Jacket online, or call customer service at 1-800-548-GARD (4273) today for

more information or to place an order.

|

| |

|

| |

Vendor Product Spotlight: Accuform® TAR114 Tags-By-The-Roll: DANGER DO NOT OPERATE (LOTO) |

| |

|

| |

Stop wasting time searching for the tags you need right away

with Accuform® TAR114

Tags By-The-Roll. Prevent your workers from misplacing their

tags before they get to work by carrying Tags-By-The-Roll to jobsites or

worksites. Tags-By-The-Roll provide a convenient solution for keeping a large

quantity of tags readily available and organized in one octagon-shaped

disposable dispenser.

When you need a tag, simply separate at the perforations and

place your Accuform® TAR114

Tags By-The-Roll: DANGER DO NOT OPERATE (LOTO) Tags on hazardous

energy sources or wherever needed to keep others safe. Tags-By-The-Roll are

durable, tear-and water-resistant, and are available with stock and custom

legends.

Additional features and benefits include the following:

- Identify temporary hazard until that hazard is eliminated or

hazardous operation is complete

- Comply in accordance with OSHA 29 CFR 1910.145 and ANSI Z535

requirements

- Thin, flexible 10-mil poly-based cardstock tags that are

connected end-to-end with perforations and housed in an innovative, convenient,

portable cardboard dispenser providing a large quantity of tags to be readily

available

- 6 5/8” x 6 5/8” x 3 5/8” octagon-shaped dispenser has 1 ½”

perforated center hole that can be removed for mounting

- PF-Cardstock tags have no wood content, are longer-lasting,

durable, tear-resistant, waterproof, and will not crack, distort, or shrink

when compared to traditional paper cardstock

- Easy to write on matte surface has 3/8” plain top,

pull-resistant hole

- 100/roll; sold by the roll

Click here

to shop the Accuform® TAR114

Tags By-The-Roll: DANGER DO NOT OPERATE (LOTO) Tags online, or call customer service at 1-800-548-GARD (4273) today for

more information or to place an order.

|

| |

|

| |

Are You Wearing the Right Apparel for the Controlled Environment?

|

| |

|

| |

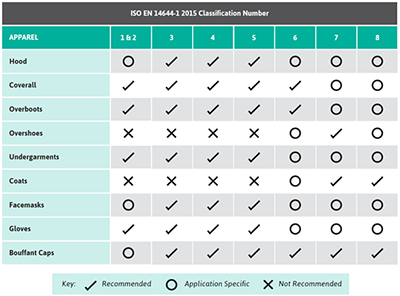

Selecting the right consumables for use in your ISO Class

cleanroom is vital in order to protect the sensitive Life Sciences processes

being performed, whilst ensuring the finished products stay protected from

sources of potential contamination.

There is currently no international standard for consumables

worn within the cleanroom, instead the cleanrooms themselves have a cleanliness

classification which is known as the ISO Class. The standard defines the

maximum allowable concentration of particles per square meter for eight Class

of cleanroom ranging from 1 – 8, with 1-3 being the cleanest, and which do not

normally have any or very limited human intervention.

The biggest source of contamination to a cleanroom are humans,

whom shed up to 100,000 particles per minute when sitting/standing, so it’s

imperative that the appropriate clothing is worn to contain contamination and

stop it from entering the controlled environment. In state-of-the-art ISO Class

4 cleanrooms no more than 352 particles of size 0.5µm per cubic meter may be

present, and in an ISO Class 5 no more than 3520 particles.

The IEST-RP-CC003.3 standard for Garment system

consideration for cleanrooms and other controlled environments, recommends the

best practice for gowning of personnel as a critical aspect of cleanroom

contamination control. The suggested garments which should be worn within each

classified area include – Coveralls, Hoods, Overboots, Gloves, Face Masks and

Undergarments.

Outlined below is guidance for the selection of garments or apparel

and accessories appropriate for use in cleanrooms and controlled environments:

It’s also essential that cleanroom clothing is manufactured

using the correct types of fabrics suitable for cleanrooms and controlled

environments.

When selecting garments for cleanroom use, depending on the

specific application, the IEST standard recommends evaluating the fabric

properties including testing for (selecting those relevant to the fabric type):

- Cleanliness and cleanability

- Electrostatic properties

- Biological properties

- Durability

- Comfort

- Opacity

- Particle filtration efficiency

- Microbial penetration

- Chemical compatibility

- Fluid resistance

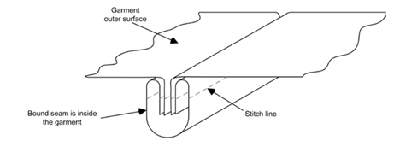

Construction of cleanroom garments is another important

consideration, and the IEST standard outlines recommendations for thread and

seam structure. Seams for cleanroom garments should be joining seams to avoid

free-air/particulate passage from the inside of the garment to the outside

environment. The IEST standard recommends for the construction of cleanroom

garments that they are constructed using a bound joining seam, as shown below:

BioClean-D™ Disposable cleanroom garments are manufactured according

to the recommendations set out within the IEST-RP-CC003.4 standard, using the

most effective barrier fabric and the best seam joining for containment of

particles and fibers.

Click here to download the technical release to find

out more information on the composition and structure of cleanroom garments.

|

| |

|

| |

The Physiological Response of Working in Cold Environments and How Your PPE Can Help |

| |

|

| |

Recent NIOSH science blogs have discussed the physiological

impact of wearing respirators. The first blog in this vein explored the Physiological Burden of Prolonged PPE Use on Healthcare

Workers during Long Shifts, including potential CO2 buildup.

A second blog addressed Heat Stress Imposed by PPE Worn in Hot and Humid

Environments and how healthcare workers and their employers

can recognize and mitigate potential stressors. As a third installment of this

series, this blog addresses the general physiological responses to cold stress

while working in cold environments and how personal protective equipment (PPE)

can provide some protection.

Incidence of Hypothermia or Cold

Injury

Due to the lack of a standardized reporting system, the true

incidence of cold injury is not known, but appears to be uncommon across most

of North America except in the northern tier states, including Alaska.

- In 2019, about 1300 people in the U.S. died of hypothermia

- 420 of these deaths, about 32%, were occupationally related

Many occupations require employees to work in cold outdoor

environments (construction, first responders including search and rescue, North

Sea oil and gas workers, etc.). Therefore, it is important to define cold

stress and injury, identify the means to mitigate the exposure to cold, and

provide immediate treatment for cold injury if necessary. Many of these

occupations also require the use of PPE. This begs the question, what is the

role of PPE in the mitigation of cold stress?

Definitions

Cold stress refers

to environmental conditions (e.g., air temperature/humidity, windchill

temperature, rain, and inadequate clothing for protection) in which body heat

is lost to the environment at a rate that is faster than the body can produce

heat. Consult the U.S. Customary Windchill Chart, an integration

of air temperature and wind velocity, to provide an estimate of the cooling

power of the environment. (Note that persons riding in open vehicles may be

subjected to dangerous wind chills even when the natural wind velocity is low).

Cold strain refers

to the physiological responses (e.g., attempts to compensate for body heat loss

through vascular changes, increased metabolic production of heat, and

shivering) involved in preventing or limiting body heat loss. Cold stress may

progress to cold injury and illness. Cold injuries may include hypothermia

(clinical hypothermia is defined as a core body temperature falling below 96.8ºF [35ºC]), frostbite (freezing of tissue causing damage to the skin and

perhaps underlying tissue), non-freezing injuries such as immersion foot

(following reduction of blood flow after exposure to cold and wet environments

which can cause nerve damage), chilblains (redness and swelling of skin of

hands, face after exposure to cold), and cracked skin. As the victim becomes

colder, they may experience muscle rigidity, reduced blood pressure,

cardiovascular effects (rhythm disturbances) and a decrease in respiratory

rate. Cold strain may also involve psychological impact to body heat loss, such

as cognitive decline, poor judgement (paradoxical removal of clothing), and

clouded consciousness.

Hypothermia: Symptoms and

Treatment

- Early Symptoms

- Shivering – attempt to generate heat

- Fatigue

- Loss of coordination

- Confusion and disorientation

- Late Symptoms

- No shivering

- Blue skin

- Dilated pupils

- Slowed pulse and breathing

- Loss of consciousness

- Cardiac dysfunction, cardiac standstill (“flatline”) (established by medical professionals in an emergency department)

- Brain – Isoelectric EEG (“flatline”) (established by medical professionals in an emergency department)

Can PPE Help Protect Against

Cold Strain?

PPE, as the last level of defense within the hierarchy of

controls, is worn to protect against specific external hazards

found in occupational settings. However, some PPE is, by its nature, highly

insulative in addition to its other protective features. Therefore, wearing

insulative PPE when available can be protective in cold environments if the PPE

remains dry. Some examples of cold protective PPE are:

- Insulated coveralls, bunker gear, and jackets

- Insulated waterproof work boots and gloves

- Insulated hoods, facepieces, and goggles

Click here to read more and learn about recommendations for employers and how to make your

clothes work for you while you work!

|

| |

|

| |

|

Watch the FREE Managing Gas Detection Programs in Manufacturing and Transportation Webinar ON DEMAND Today

|

| |

|

| |

Join Robert Henderson, the President of GfG Instrumentation,

Inc., a supplier of portable and fixed gas detection and indoor air quality

monitoring products, as he examines the common challenges and presents solutions

for maintaining a gas detection program in manufacturing and transportation settings,

including managing compliance, personnel, and the products.

Click here to register, and watch the FREE

webinar ON DEMAND today!

|

|

|

|

|

|

|

| National Emphasis Program |

|

|

|

|

OSHA launched a national emphasis program to protect

high-risk workers from COVID-19 hazards. The program also prioritizes employers

that retaliate against workers who complain about unsafe or unhealthful

conditions.

What is a national emphasis program and why does OSHA institute

them?

National Emphasis Programs (NEPs) are temporary programs that

focus OSHA resources on particular hazards and high-hazard industries.

New and existing programs are evaluated using inspection data, injury and

illness data, National Institute for Occupational Safety and Health reports,

peer-reviewed literature, analysis of inspection findings, and other

information.

|

|

|

|

|

|

Masks Block More Cough Aerosol Particles than Face Shields

|

|

|

|

|

CDC recommends wearing face masks in all public settings to help

prevent the spread of COVID-19. NIOSH recently tested face masks, neck gaiters,

and face shields to see how well they block the small aerosol particles

produced by people when they cough. NIOSH asked lead author William Lindsley,

NIOSH biomedical research engineer, to explain the study, published in the journal Aerosol Science and Technology. Click here to read more on his responses to the efficacy

of the different types of face coverings, if there are any face coverings that often that are not effective, if any face covering is better than no

covering and what questions remain.

|

|

| |

|

| Saf-T-Gard Catalog |

|

|

|

|

The time for better safety is now!

Click here to request a FREE copy of our current full-line Saf-T-Gard International, Inc. catalog today, and learn how to better GARD yourself with Saf-T-Gard.

Featuring more than 3,900 different line items from more than 100 different brands and fourteen (14) different product categories, this catalog is an excellent resource and provides a wealth of information to help keep you safe and productive for even the most rigorous applications!

|

|

| |

|

|

|

| Closeout Corner - Don't Miss These Great Deals |

|

|

|

|

Saf-T-Gard is making it easier than ever to save big on your favorite safety items with the "Closeout Corner" featured monthly in the Saf-T-Gardian

e-Newsletter.

Click here to view the reduced pricing on all of your must-have items to take advantage of this limited-time pricing and inventory.

Be sure to check back next month for even more products and savings!

|

|

|

|

|

Visit with Saf-T-Gard Virtually

|

|

|

|

|

Hazards exist in every workplace. Common examples include slips,

trips, falls, exposure to loud noises, working from heights, vibrations and

unguarded machinery. The best way to protect your employees is to recognize the

hazards that exist on the job, and control them by utilizing the appropriate

personal protective equipment (PPE) for the application.

This is where Saf-T-Gard can

help! We've been bringing workers home safely since 1936 with our finest

industrial safety products and PPE, and we can do the same for you. Stop by our virtual booth at the following trade show to check out our

comprehensive selection of safety products and services that directly address

every workplace safety hazard.

Wisconsin Safety Council Annual Conference - Tuesday, April 20, 2021 from 8:00 a.m. to 12:45 p.m. (CST),

Wednesday, April 21, 2021 from 8:00 a.m. to 12:45 p.m. (CST),

Thursday, April 22, 2021 from 8:00 a.m. to 12:45 p.m. (CST),

Thursday, April 22, 2021 from 8:45 a.m. to 9:45 a.m. (CST) - Richard Rivkin’s Presentation: “A Shocking Need for Electrical Safety,

Inspection & Testing”

|

|

| |

|

| Safety Tips |

|

|

|

|

1. ANTI-NOISE - Disposable, expandable foam earplugs offer convenient, low-cost ear

protection

2. ANTI-NOISE - Pre-molded, reusable earplugs are washable and are often available in

different sizes for a better fit

3. ANTI-NOISE - Canal caps on a headband or neckband offer the lightweight convenience

of being able to easily and quickly remove the ear protection when not needed

4. ANTI-NOISE - Earmuffs come in many different styles, sizes, weights, and profiles

5. ANTI-NOISE - Earmuffs are also available as a cap-mounted attachment for those who

wear safety caps

|

|

| |

|

| Q&A |

|

|

|

|

|

Question – “Does OSHA mandate that all volunteer members of a HAZMAT team be

required to participate in medical surveillance, or may an employee opt out of

medical surveillance?”

Answer - Medical surveillance requirements for personnel involved in emergency

response to the release of hazardous substances, i.e., HAZMAT team members, are

set forth in 1910.120(q)(9). Paragraph 1910.120(q)(9)(i) provides:

"Members of an organized and designated HAZMAT team and hazardous

materials specialists shall receive a baseline physical examination and be

provided with medical surveillance as required in paragraph 1910.120(f) of this

section." Therefore, HAZMAT team members involved in emergency response

operations covered by 1910.120(q)(9)(i) must receive a baseline physical exam.

Any employee subject to 1910.120(q)(9) who elects not to have a baseline

examination may not perform emergency response duties as part of a HAZMAT team

or as a hazardous materials specialist. An employee who is a

"volunteer" member of a HAZMAT team or hazardous materials specialist

must still receive the baseline examination under paragraph 1910.120(q)(9)(i).

That paragraph applies to all members of any organized and designated HAZMAT

team. Any employee who is expected to respond to hazardous substance releases

as a HAZMAT team member with the knowledge of the employer is covered under the

requirements.

|

|

| |

|

| Saf-T-Gard Spotlight |

|

|

|

|

Ellie McGivern is our marketing specialist. She has worked at

Saf-T-Gard since September 2014, starting first as a marketing intern before

beginning promoted to a marketing coordinator in May 2015 and marketing

specialist in August 2018.

What Ellie likes about Saf-T-Gard:

“I enjoy the creative freedom I have in designing graphics that

reflect Saf-T-Gard’s established brand and learning all the ins and outs about

the company.”

What makes Ellie's day:

“Getting everything on my to-do list accomplished!”

Ellie’s outside interests:

“I enjoy spending my time cooking up new recipes and listening

to music.”

Anything else?

“I

am glad to be a part of the Saf-T-Gard team, and I look forward to seeing what

the future holds!”

|

|

| |

|

Factoid Factoid |

|

|

|

|

Who is responsible for providing the quick drenching and flushing

facilities where there is exposure to corrosive materials? Are small businesses

(e.g., retail stores) subject to 29 CFR 1910.151(c), if they handle corrosive

liquid materials?

Every employer with employees exposed to the corrosive chemicals is

responsible for the safety and health of their employees. Paragraph (c) of 29

CFR 1910.151 requires that suitable facilities for quick drenching or flushing

be provided within the work area for immediate use if an employee's eyes or

body may be exposed to corrosive materials. The OSHA standard does not set

specifications for emergency eyewash and shower equipment, but we agree that

equipment that complies with ANSI (ANSI Z358.1-2004, American National Standard

for Emergency Eyewash and Shower Equipment) requirements would usually meet

the intent of the OSHA standard. It should also be noted that, in addition to

the requirement for emergency flushing and drenching facilities, there are also

requirements for personal protective equipment (PPE) when employees are exposed

to the hazards in which corrosive chemicals are present. PPE requirements are found in

Subpart I, Personal Protective Equipment, of 29 CFR §1910 and may include, but

are not limited to, protection for the eyes, face, and hands, as well as

protective clothing. The purpose of PPE is to prevent injury, whereas the

purpose of the eye wash or shower is to minimize injury, should that first line

of defense fail. And yes. All employers, regardless of size, that have

employees whose eyes or body may be exposed to injurious corrosive materials

must provide quick drenching and flushing facilities.

|

|

| |

|

| As I See It |

|

|

|

|

It is March 2021 and maybe, just maybe, our long dark

Year-Of-The-Pandemic is actually improving. Without getting political, the

combination of 3 vaccines approved for Emergency Use plus other measures taken

over the past 12 months seems to be reducing the numbers of cases,

hospitalizations, and fatalities.

So what have we learned so far from this pandemic, from a safety

perspective? First of all, trust your PPE and your PPE supplier. There are

continuing horror stories of fake and counterfeit N95 respirators which put

people’s lives at risk. And there are other horror stories of disposable gloves

being sold with counterfeit FDA certificates and questionable quality. If you

wouldn’t buy food or medicine at a hardware store (and I like most hardware

stores), then you shouldn’t buy PPE from non-safety-specialists.

Secondly, a pandemic-forced acceptance with virtual meetings

(Zoom, etc.) means that we can provide customers with access to safety product

technical specialists from anywhere in the world without regard to travel

schedules. Need to understand technical details such as OSHA PELs for chemical

exposure – we can get a specialist to explain it.

Third, we are all more cautious about visitors in our

facilities. The nice person who refills the first aid kit or cabinet or the

other nice person who refills the PPE vending machine can be health risks to

your workplace and workforce. We have technological and process solutions to

eliminate those risks while gaining a high degree of efficiency,

accountability, responsibility, and practicality.

How

do we know this? Because we are Saf-T-Gard International - Bringing

Workers Home Safely Since 1936.

|

|

|