The site navigation utilizes arrow, enter, escape, and space bar key commands. Left and right arrows move across top level links and expand / close menus in sub levels. Up and Down arrows will open main level menus and toggle through sub tier links. Enter and space open menus and escape closes them as well. Tab will move on to the next part of the site rather than go through menu items.

TESTING STANDARDS FOR RUBBER INSULATING PRDODUCTS

OSHA rules and NFPA standards make the use of rubber insulating products mandatory when even the smallest probability of contact with 50 volts AC or higher exists. These rules affect nearly all industrial workplaces, as every single facility (including utility contractors and general contractors) has a need for electrical safety and arc flash protection, and failure to comply can result in heavy fines, serious injury and even death. Moreover, OSHA and ASTM standards also require regular inspection and testing of in-service electrical protective equipment in order to maintain compliance and ensure the products’ safety and integrity when exposed to a wide range of voltages.

After a visual inspection is completed, rubber goods should be electrically tested, either at AC (alternating current) or DC (direct current) voltages depending on the application, using specialized equipment designed to gradually increase the voltage to the desired test level. The dielectric test is two-fold: Pass/fail on the ability to withstand the rated test voltage and, for gloves, quantitative on the ability to prevent electric current from passing through the rubber goods above the maximum contained in the specifications. Products passing the inspection and test procedures can then be returned to service. Electrical testing also helps to increase savings. Rubber insulating products are costly, and many times these costs are unnecessarily increased by purchasing replacements for products that could have remained in service with the proper in-service care, testing and recertification.

TESTING PROCESS

At a minimum, ASTM standards require that the inspection and testing process include the following steps:

Check-in

Removing previous testing marking

Washing using cleaning agents that will not degrade the insulating properties

Visual inspection of all surfaces (inside and out)

Electrical testing

Final inspection

Recordkeeping

Marking

Packing in appropriate containers for storage or shipment (“appropriate containers” means boxes, or similar sturdy packaging materials to prevent folding, creasing or similar loose storage that can cause stress on the rubber)

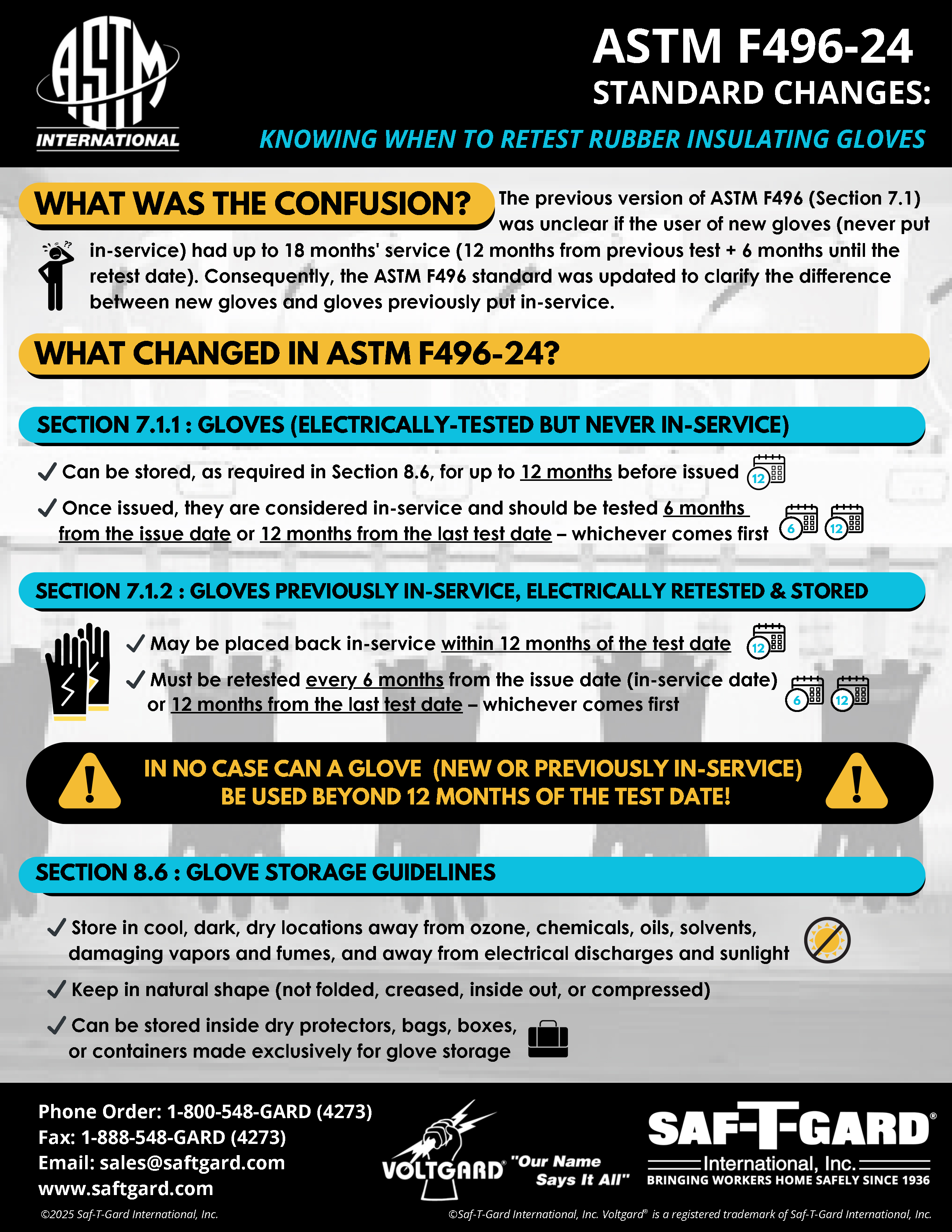

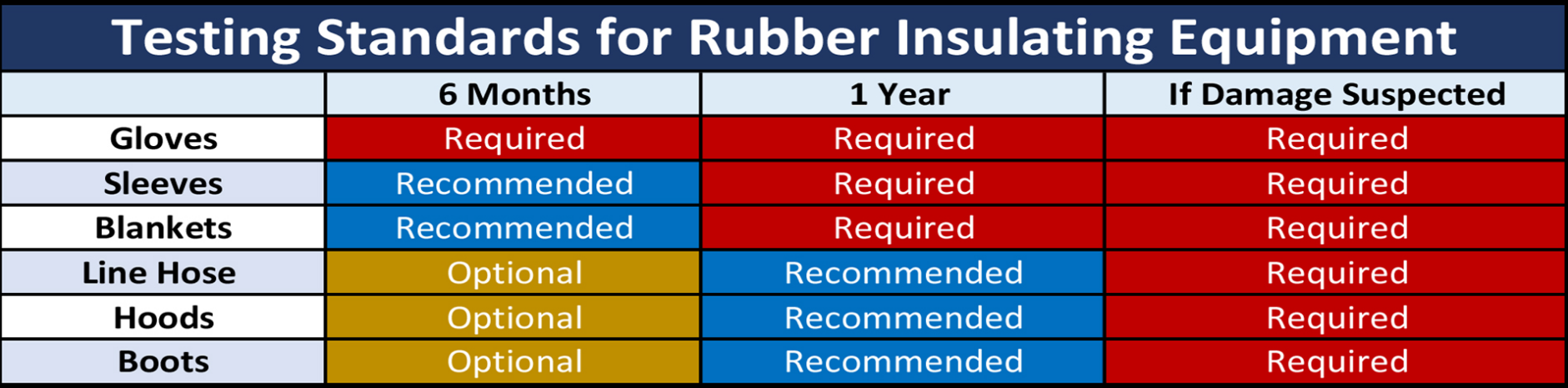

TESTING INTERVALS

The interval between the date of issue and electrical testing should be based on work practices and test experience. For gloves, the interval shall not exceed 6 months except for industries such as telecommunications that utilize insulating gloves as precautionary protection, in which case the maximum interval may be increased to 9 months. For sleeves and blankets, the interval shall not exceed 12 months. For line hose and covers, no minimal maximum interval is specified; Electrical testing shall be performed if the periodic cleaning and visual inspection identifies conditions that might adversely affect performance and safety.

Keep in mind that all electrical protective rubber insulating products are tested by the manufacturer prior to the first shipment. End users (or an end users’ designee) may perform acceptance testing within the first 2 months after receipt. However, do not place rubber insulating products into service unless they have been tested electrically within the previous 12 months.

THE VOLTGARD® TEST LAB

Saf-T-Gard's Voltgard® Test Lab can manage all of this for you by providing full dielectric testing and recertification services for users of rubber insulating products in every industry, including electric utilities, contractors, telecom, municipalities, first responders, and industrial facilities. The Voltgard® Test Lab is equipped to clean, inspect, and perform dielectric testing of:- Rubber Insulating Gloves

- Rubber Insulating Sleeves

- Rubber Insulating Blankets

- Line Hose

- Covers

- Jumper Cables

- Grounding Sets

- Plastic Guards

- Hot Sticks

- Matting

- Hoods

- Hand Tools

*Replacements are available for any failed products to ensure that your workers have the protective equipment that they need. Inventory management and scheduled change-out programs are also available.

All inspection and testing conducted by the The Voltgard® Test Lab are performed in strict accordance with applicable ASTM specifications. The The Voltgard® Test Lab is accredited by NAIL4PET to test the products below to the applicable ASTM standards:

- Insulating Gloves ASTM D120, F496, F1236

- Insulating Sleeves ASTM D1051, F496, F1236

- Insulating Blankets ASTM D1048, F479, F1236

- Insulating Line Hose ASTM D1050, F478, F1236

- Insulating Covers ASTM D1049, F478, F1236

- Dielectric Overshoe Footwear ASTM F1116, F1117

- Insulating By-Pass Jumpers ASTM F2321, F2249

- Portable Grounding Jumpers ASTM F2249, F855

- Hot Sticks/Line Tools ASTM F711, IEEE 978, F1825

- Insulating Plastic Guards ASTM F712

- Insulating Hand Tools ASTM F1505

- Rubber Insulating Matting ASTM D178