How to Better Protect Your Industrial Workers against Arc Flash & Electrical Incidents with Electrical Gloves

What is Arc Flash and How Does it Cause Shock Hazards?

According to the National Fire Protection Association (NFPA), arc flash is an electric current that passes through the air when insulation or isolation between electrified conductors is no longer sufficient to withstand the applied voltage. Arc flash can be initiated through accidental contact, equipment which is underrated for the available short circuit current, contamination or tracking over-insulated surfaces, deterioration, or corrosion of equipment and/or parts, as well as other causes. Most often when there is an arc flash hazard there is also a shock hazard since arc flash hazards involve or are near energized equipment. OSHA estimates that 80 percent of electrically-related accidents and fatalities involving “Qualified Workers” are caused by arc flash/arc blast.

Why is Arc Flash and Electrical Safety Important?

Electrical safety is not only a concern for utility workers or contractors. Every workplace today operates on electricity, and the danger of exposure to arc flash and electrical incidents continues to increase as workers’ responsibilities expand to include interaction with electrical equipment. Nearly every single facility has a need for electrical safety, whether the company is a larger facility with building engineers overseeing distribution, or a smaller facility with maintenance staff working around floor or wall sockets. Nowadays, maintenance workers, janitorial staff, facilities staff, and equipment operators (not just electricians) all risk exposure to electrical shock, making the need for stringent safety standards even more imperative since nothing is minor when it comes to arc flash and electrical injuries. Workers might walk away from a fall, but an arc burn, or electric shock will almost always require serious medical attention. If an open electric circuit comes in contact with a human body, it will get a shock. The electric current will pass through the body from one point to another causing great pain, burns, damage to the tissues, nerves and muscles and can even result in death. While arc flash and electrical hazards are not the leading cause of on-the-job injuries and accidents, they are disproportionately fatal and costly. These injuries not only disrupt the lives of the workers and their families, but also impact the productivity of employers. The good news is that most on-the-job electrocutions and electrical injuries can be prevented by following a few basic steps to help protect workers and employers against loss time injuries, costly damage to equipment and facilities, legal liability, increased insurance premiums and hefty regulatory fines.

Electrical safety is not only a concern for utility workers or contractors. Every workplace today operates on electricity, and the danger of exposure to arc flash and electrical incidents continues to increase as workers’ responsibilities expand to include interaction with electrical equipment. Nearly every single facility has a need for electrical safety, whether the company is a larger facility with building engineers overseeing distribution, or a smaller facility with maintenance staff working around floor or wall sockets. Nowadays, maintenance workers, janitorial staff, facilities staff, and equipment operators (not just electricians) all risk exposure to electrical shock, making the need for stringent safety standards even more imperative since nothing is minor when it comes to arc flash and electrical injuries. Workers might walk away from a fall, but an arc burn, or electric shock will almost always require serious medical attention. If an open electric circuit comes in contact with a human body, it will get a shock. The electric current will pass through the body from one point to another causing great pain, burns, damage to the tissues, nerves and muscles and can even result in death. While arc flash and electrical hazards are not the leading cause of on-the-job injuries and accidents, they are disproportionately fatal and costly. These injuries not only disrupt the lives of the workers and their families, but also impact the productivity of employers. The good news is that most on-the-job electrocutions and electrical injuries can be prevented by following a few basic steps to help protect workers and employers against loss time injuries, costly damage to equipment and facilities, legal liability, increased insurance premiums and hefty regulatory fines.

How to Establish Safe Work Practices

While the best way to prevent arc flash or electrical incidents from happening is to de-energize equipment before beginning work, there are instances when turning off the power could create an even greater hazard. Therefore, employers and facility owners must establish safe work practices including the use of personal protective equipment.

Employees who work on electrically-energized circuits and equipment use their hands, making them the most susceptible part of the body to electric shock. Arc-rated work gloves offer no shock protection, and most arc flash hazards have a shock exposure hazard as well. The NFPA along with the Occupational Safety and Health Administration (OSHA) mandates and enforces safer electrical work practices under the NFPA 70E standard. Numerous experts and training programs are available to provide guidance on how to keep workers safe and compliant in terms of conducting a proper hazard assessment and selecting the appropriate PPE. However, one topic that is not discussed in detail is the need for rubber insulating gloves where a shock hazard exists from exposure to energized equipment.

Rubber Insulating Gloves to the Rescue

Rubber insulating gloves are the only protective gear designed for constant contact with, and protection from, energized conductors and equipment. All the other items are designed for protection from accidental, incidental or brush contact. Arc-rated work gloves alone provide no protection from live voltage. OSHA rules and the NFPA 70E standard make the use of rubber insulating products mandatory when even the smallest possibility of contact with 50 volts AC or higher exists.

Rubber insulating gloves are an essential element in protecting workers that are exposed to high-voltage currents. Shock protection is the primary benefit. However, rubber insulating gloves also provide significant burn protection in the event of an arc flash. Rubber insulating gloves are manufactured using proprietary materials and manufacturing processes with 100% testing to provide the highest level of protection. To be effective, rubber insulating gloves must incorporate high dielectric and physical strength, along with comfort, flexibility, and durability. To help ensure safety and performance, they should meet and/or exceed the requirements of the American Society of Testing Materials (ASTM) D120-14a – Standard Specification for Rubber Insulating Gloves.

How to Choose the Rubber Insulating Glove That’s Right for You

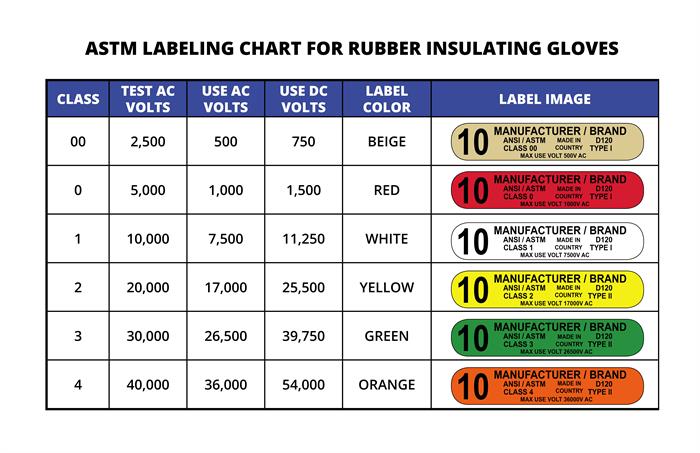

According to the OSHA 29 CFR 1910.137 standard, rubber insulating gloves must be rated for the voltage to which a worker will be exposed (phase to ground or phase to phase) and marked to indicate their rating. For in-service use, the maximum use voltage must be above the actual exposure, but it is important to take note of the proof test voltage as well. All rubber insulating gloves are tested by the manufacturer at the specified proof test voltage. Manufacturers also perform a dielectric breakdown test at an even higher voltage to validate the dielectric strength of the rubber material. The result is a significant margin of safety between the test voltages and the maximum use voltage. Each specific hazard assessment will help in determining which class of gloves is appropriate for the application.

Take care to choose the correct rubber insulating gloves for the task at hand and level of electrical exposure. Rubber insulating gloves are typically manufactured in sizes 8-12, often in half sizes, and some manufacturers also offer gloves as small as size 7 and as large as size 13. In addition, rubber insulating gloves are available in different cuff lengths of 11, 14, 16 and 18 inches depending on the glove class. Rubber insulating gloves are available in six specific voltage classes (Class 00 – Class 4) categorized by the level of voltage protection they provide and whether they are resistant to ozone. For gloves, ozone resistance is covered by the “Type” designation. A Type I glove is not ozone-resistant, while a TYPE II is ozone-resistant and is manufactured from a synthetic polymer that is also more resistant to many chemicals. Voltage protection is broken down into the following classes:

Please note this chart includes DC voltages as the ASTM standards also include DC test and maximum use voltages.

Please note this chart includes DC voltages as the ASTM standards also include DC test and maximum use voltages.

Gloves and other rubber insulating products must be permanently marked to indicate the voltage class, and the gloves and sleeves must also have a color-coded label identifying the voltage class.

How to Measure Rubber Insulating Glove Size

Make sure to choose the right glove size, as proper fit will ensure the likeliness that the workers will wear the electrical gloves. Gloves that are too big or bulky can affect tactile sensitivity, while gloves that are too small can cause discomfort. ASTM D120 section 8.2 provides the measurements of the diameter of the palm for manufacturers, measured at the midpoint of the palm, plus or minus a ½ inch. Measure the hand by wrapping the tape all the way around the palm. This number would equate the probable size of the glove to select. Personal preference for tightness and finger length will ultimately determine the size that the wearer will choose.

Make sure to choose the right glove size, as proper fit will ensure the likeliness that the workers will wear the electrical gloves. Gloves that are too big or bulky can affect tactile sensitivity, while gloves that are too small can cause discomfort. ASTM D120 section 8.2 provides the measurements of the diameter of the palm for manufacturers, measured at the midpoint of the palm, plus or minus a ½ inch. Measure the hand by wrapping the tape all the way around the palm. This number would equate the probable size of the glove to select. Personal preference for tightness and finger length will ultimately determine the size that the wearer will choose.

How to Protect the Gloves that Protect You

Equal care and consideration should also be given when selecting the appropriate leather protector gloves. With very few exceptions, leather protector gloves must always be worn over rubber insulating gloves to extend their life and provide protection to the gloves from cuts, abrasions, and punctures. Moreover, the OSHA "269" standard (29 CFR 1910.269) requires that rubber insulating gloves along with leather protector gloves must be worn by 269-qualified employees within the Minimum Approach Distance to exposed energized conductors. Use the ASTM F696 standard specifying the types of materials, construction, and other details as a guide in the selection process. Keep in mind that there is a tracking and flashover risk which increases as the voltage potential increases. Since the materials in the leather protector gloves have no dielectric properties and may absorb moisture or at least track electricity, it is important to maintain an interval between the leather protector gloves and the wearer’s body parts, i.e., hand and arm. Therefore, the leather protector gloves must be shorter than the rubber insulating gloves so that there is exposed rubber as a line of defense against tracking and flashover. The applicable ASTM specifications state that the minimum distance between the edge of the leather protector and the cuff edge of the rubber insulating glove is ½ inch for low-voltage gloves and 1 inch per glove class for high-voltage gloves. Knowing this, the leather protector gloves for Class 2 rubber insulating gloves must be at least 2 inches shorter than the rubber insulating glove.

Equal care and consideration should also be given when selecting the appropriate leather protector gloves. With very few exceptions, leather protector gloves must always be worn over rubber insulating gloves to extend their life and provide protection to the gloves from cuts, abrasions, and punctures. Moreover, the OSHA "269" standard (29 CFR 1910.269) requires that rubber insulating gloves along with leather protector gloves must be worn by 269-qualified employees within the Minimum Approach Distance to exposed energized conductors. Use the ASTM F696 standard specifying the types of materials, construction, and other details as a guide in the selection process. Keep in mind that there is a tracking and flashover risk which increases as the voltage potential increases. Since the materials in the leather protector gloves have no dielectric properties and may absorb moisture or at least track electricity, it is important to maintain an interval between the leather protector gloves and the wearer’s body parts, i.e., hand and arm. Therefore, the leather protector gloves must be shorter than the rubber insulating gloves so that there is exposed rubber as a line of defense against tracking and flashover. The applicable ASTM specifications state that the minimum distance between the edge of the leather protector and the cuff edge of the rubber insulating glove is ½ inch for low-voltage gloves and 1 inch per glove class for high-voltage gloves. Knowing this, the leather protector gloves for Class 2 rubber insulating gloves must be at least 2 inches shorter than the rubber insulating glove.

Connect with Saf-T-Gard to Learn More

Industrial safety is our legacy going back 9 decades, and electrical safety is our specialty. Click here for answers to some of the most frequently asked questions about rubber insulating products. For an overview of our electrical safety products and services, please visit Arc Flash & Electrical Safety.