Hidden Explosive Environments: What are the Dangers and How Can They be Avoided?

The dangers of explosive environments are obvious in the petroleum and chemical processing industries, but many other industries can create explosive atmospheres that are not as obvious but still represent a serious danger.

Examples illustrating this are facilities that process grains, sugar, metal powders, and wood products In 2018 grain handling facilities in Nebraska and eastern France were destroyed or seriously damaged by grain dust explosions. In 2008 an explosion wrecked a sugar refinery in Georgia, killing 14 people and injuring another 40. Five workers were fatally injured in an iron dust fire in Tennessee in 2011. It is essential to understand the conditions that can create explosive environments and the proper equipment required to enter them safely.

Examples illustrating this are facilities that process grains, sugar, metal powders, and wood products In 2018 grain handling facilities in Nebraska and eastern France were destroyed or seriously damaged by grain dust explosions. In 2008 an explosion wrecked a sugar refinery in Georgia, killing 14 people and injuring another 40. Five workers were fatally injured in an iron dust fire in Tennessee in 2011. It is essential to understand the conditions that can create explosive environments and the proper equipment required to enter them safely.

What Equipment is Required for Explosive Environments?

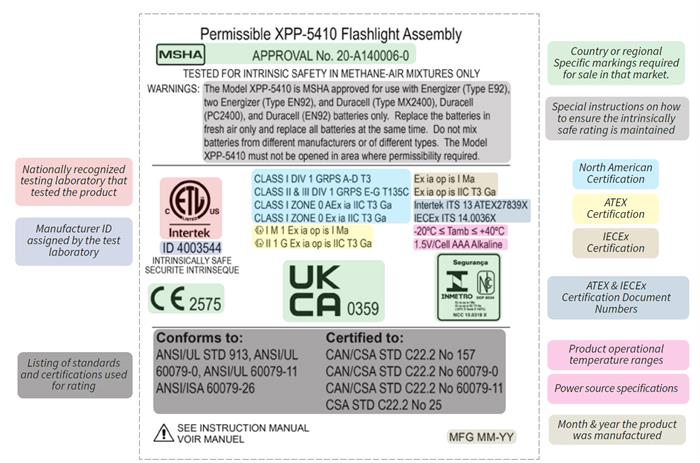

The equipment you are using must meet or exceed the standards for the most explosive environment you could face under known or unknown situations. In the United States, Intrinsically Safe (IS) products are tested to the UL 913 5th or 8th edition standards with the UL 913 8th edition being harmonized to the EN/IEC 60079-01/-11 standard for European Union ATEX certifications and the remaining countries IECEx certifications.

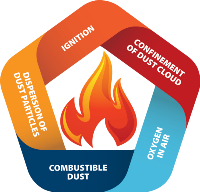

For an explosion to occur, five components must be in place: oxygen, confined space, ignition source, dispersion, and a fuel source. These elements make up the explosion pentagon. The three elements needed for a fire — fuel source, oxygen, and an ignition source — can create a flash fire within a confined space, resulting in the ingredients for an explosion. Eliminating one of these five elements will prevent an explosion, but eliminating these hazards is not a simple process. Oxygen in confined spaces typically cannot be eliminated. Therefore, managing fuel sources and the use of properly rated equipment to prevent ignition is essential.

source — can create a flash fire within a confined space, resulting in the ingredients for an explosion. Eliminating one of these five elements will prevent an explosion, but eliminating these hazards is not a simple process. Oxygen in confined spaces typically cannot be eliminated. Therefore, managing fuel sources and the use of properly rated equipment to prevent ignition is essential.

As an example, using the ATEX classification system, a Zone 2 environment could quickly become a Zone 1 or even a Zone 0 environment, and your equipment must be rated appropriately as you may not be aware that the environment has changed until it is too late. If you are unsure, analyze the work environment, determine the worst-case scenario, and equip your workers based on that.

The quality of your equipment is vital in explosive environments. You must ensure it is manufactured by a reputable company with documented experience in creating intrinsically safe products. The ideal situation would be to purchase all of your IS products from a single manufacturer rather than mixing and matching products from several companies. A single source manufacturer ensures consistent quality and safety across the entire product line. Because of the knowledge, time, and expense required to engineer and produce IS products, a very limited number of companies can achieve this.

The quality of your equipment is vital in explosive environments. You must ensure it is manufactured by a reputable company with documented experience in creating intrinsically safe products. The ideal situation would be to purchase all of your IS products from a single manufacturer rather than mixing and matching products from several companies. A single source manufacturer ensures consistent quality and safety across the entire product line. Because of the knowledge, time, and expense required to engineer and produce IS products, a very limited number of companies can achieve this.